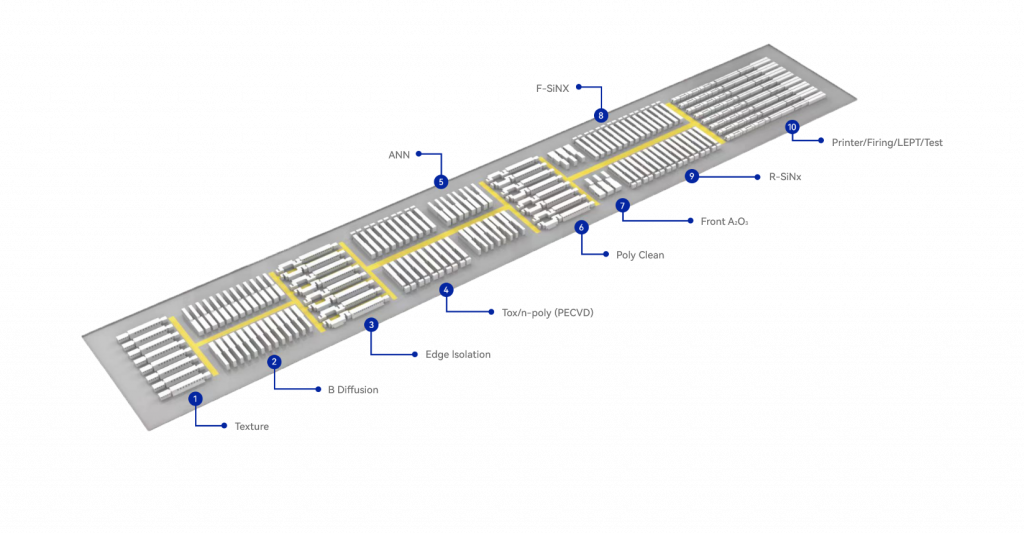

Improving the production process for photovoltaic panels is becoming more important as the demand for solar energy continues to rise. With LEAD intelligent‘s turnkey solutions, manufacturers can optimize their production using modern technology and seamless integration. This applies to the whole Topcon cell manufacturing process.

Comprehensive Turnkey Equipment for PV Panel Manufacturing Process

LEAD’s independently developed equipment covers every stage of the pv panel manufacturing process, including main cleaning, texturing, alkaline polishing, etching, polysilicon cleaning, screen printing, testing, and sorting. Fully automatic loading and unloading systems, coupled with unmanned AGVs, ensure smooth workflow and minimal downtime.

Industrial Internet and MES Integration

Equipped with industrial Internet digital solutions, LEAD Intelligent enables inline quality inspection, real-time data collection, and information integration via the MES system. This smart management of the pv panel manufacturing process improves yield rates and guarantees full life cycle traceability of PV cells.

Boosting Efficiency with Laser Enhancement Technology

The Topcon Photovoltaic Cell 3.0 benefits from LEAD’s self-developed laser enhancement technology, increasing efficiency by 0.8% and achieving a cell conversion rate exceeding 26.5%. This breakthrough positions LEAD’s pv panel manufacturing process solutions at the forefront of the solar industry.

Stable and High Production Efficiency

With LEAD Intelligent’s equipment, a single large production line can produce 20 million pieces per day, maintaining a utilization rate above 90% and an A-level product rate exceeding 98.5%, ensuring consistent quality and output.

Conclusion

LEAD Intelligent’s integrated solutions revolutionize the pv panel manufacturing process, combining advanced equipment and digital intelligence for superior efficiency, quality, and traceability.